Research: Designing 'home' on Mars and the moon

by Kathleen McCoy |

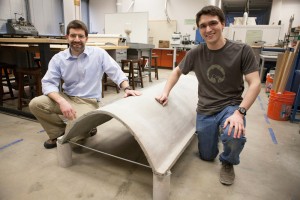

Scott Hamel, Nathaniel Cox and a thin-shell latex-modified roof unit, which inspired a different recipe for lunarcrete, a building material designed for the moon and Mars. (Photo by Philip Hall.UAA)

When life gets tense down here on Earth-climate change, civil unrest, the next election cycle-Alaskans can take comfort knowing one of their own is hard at work discovering what our future houses on Mars and the moon might look like.

That would be Nathaniel Cox, a May 2014 civil engineering graduate from UAA doing research this summer on a fellowship provided by NASA's Alaska Space Grant Program. His mission: Mix, pour and test the strength of a unique formula for concrete that could potentially shape the walls and ceilings of our extraterrestrial homes. Scientists and engineers actually call it lunarcrete.

One NASA video I watched explained that during the Apollo era's manned space missions, the agency accumulated a half ton of lunar soil. Even then, scientists realized that space travelers would one day be residents off of planet Earth. What would they live in? How would those structures be built? Hauling everything from planet Earth would be too expensive. Could building blocks be made on the moon?

Back in 1986, scientists at a technology institute in Illinois got 40 grams of moon dust and used it to make some concrete. The moon soil, called lunar regolith, replaced the more familiar sand, gravel and crushed stone typically churned together with water and cement to cure into good old reliable concrete here on Earth.

Humans have been building with concrete since the Romans. The Colosseum in Rome is made of it, and the Pantheon has the world's largest unreinforced concrete dome.

Over time, the recipe has changed. Along with water, the Romans used lime, volcanic ash and pumice. They even added horse hair to help keep it from cracking. In the 1800s, an Englishman patented Portland cement, made by mixing and heating limestone and clay and then grinding it up into a fine powder. When you add water, the cement paste glues all the rocks and sand together into concrete-something you can shape into buildings and bridges and roadways.

All Nathaniel Cox is doing, along with a number of other scientists and engineers around the world, is messing with the recipe. On other planets, what will replace the water, sand and gravel and cement we use on Earth?

Scott Hamel, a civil engineering professor at UAA, is the official mentor on the project. That means he and Cox have thrown around ideas about what might work. Cox did all the literature review, checking out what anyone else has tried, and Hamel has applied his accumulated professional knowledge as a civil engineer.

One reason Cox and Hamel were picked for this project is their ongoing work on thin-shelled, latex-modifed barrel units that could become safer roofing material for rural Alaska or in underdeveloped countries like Haiti. There, a 2010 earthquake flattened poorly constructed buildings and killed hundreds of thousands of people. Hamel was inspired to create this new roof design during a tour with Engineers Without Borders in Haiti back in 2004.

Designing lightweight strong concrete roofs that can be built in Third World countries isn't that far off from figuring out how you could build them on the moon or Mars. Of course, there are extraterrestrial challenges, but one of NASA's directives for research is developing new materials that make life better on Earth as well as in space. With their barrel units, Hamel and Cox had that nailed.

So what is their extraterrestrial recipe? No, they aren't buying any lunar dust to work with. Instead, a company funded by NASA has developed a substitute, called lunar regolith simulant, with enough of the same properties that scientists and engineers can practice with it here on Earth.

Cox, on a budget of $5,000 from NASA and another $5,000 from UAA's Innovate fund, is watching his pennies. Fifty-five pounds of lunar regolith simulant will cost $650. The recipe he and Hamel have settled on uses the imitation moon dirt, powdered latex, water and calcium aluminate cement. They are also substituting lightweight fiberglass fabric to add strength, instead of the metal mesh they used in the roof units made with Haiti in mind.

Cox is busy building the molds for his lunarcrete and designing at least six strength tests. Those are the results he'll report to NASA, with a deadline of Sept. 30.

He says he's thrilled to apply a passion for structures to something as novel as living on another planet. He credits a high school physics teacher (Bill Ennis at East High) and a calculus professor at UAA (Larry Foster) for giving him the passion to go deep and stick with solving complex problems.

NASA quoted a visionary computer scientist in that video I mentioned at the beginning. "The best way to predict the future," said Alan Kay, "is to invent it."

Who would have guessed that some of that might happen right here at UAA.

A version of this story by Kathleen McCoy appeared in the Anchorage Daily News on June 22, 2014.

"Research: Designing 'home' on Mars and the moon" is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

"Research: Designing 'home' on Mars and the moon" is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.