Projects and Uses

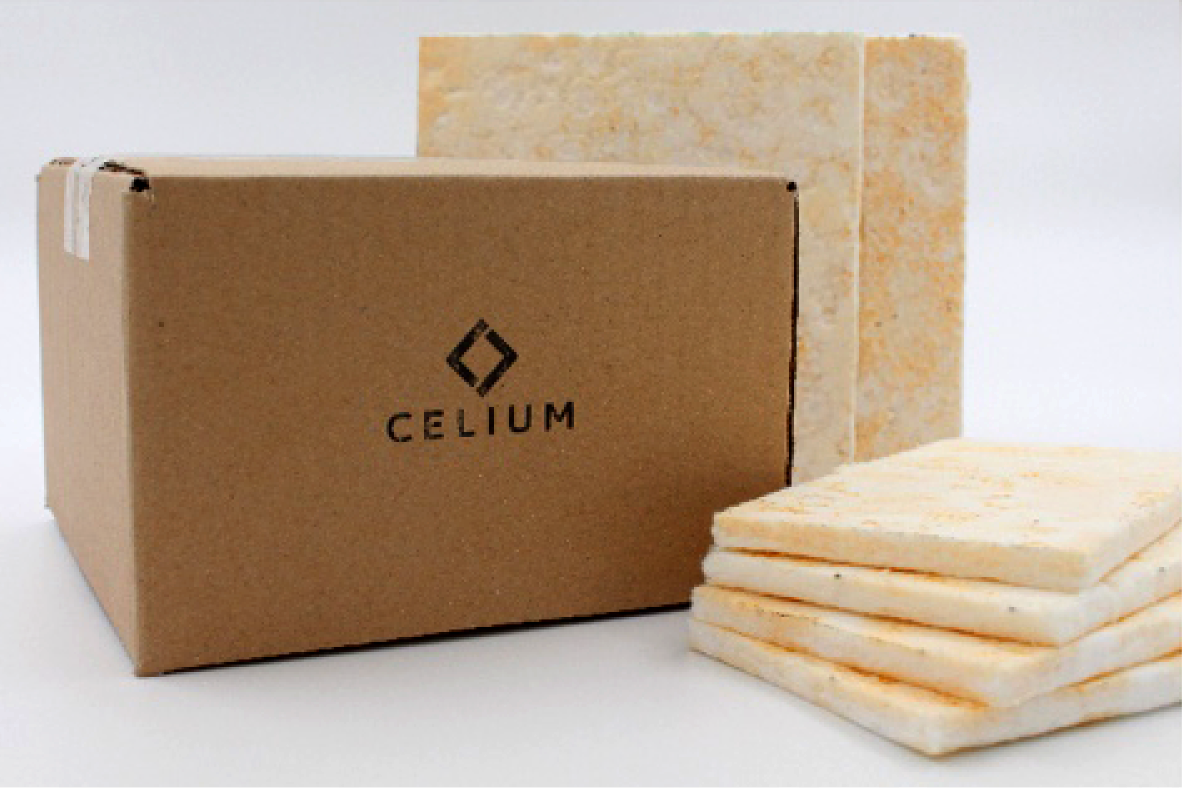

Our researchers grow and produce a biodegradable alternative to styrofoam that produces . From our process we are able to obtain foam-like materials which could be used in the future for the applications shown below. Nevertheless, these materials could have many other applications beyond the ones illustrated here.

Potential uses

Bio-based thermal and acoustic insulation for buildings

Buildings produce 40% of global CO2 emissions. Bio-based materials like mycelium-cellulose composites (MCC) can change this by turning buildings into carbon storers! In Alaska, an average home’s annual energy use is double the US average. 70% of homes are in dire need of energy retrofits to reduce heating costs and green house gas emissions. MCC can be instrumental in creating healthy and carbon-neutral homes.

Carbon-negative coolers and cold-chain shippers

Eco-friendly, bio-based coolers for camping and shipping of seafood, medicines, and other temperature-sensitive products.

Zero pollution fishing gear

Mycelium can valorize cellulose, the most abundant biopolymer on the planet, to make ocean-safe fishing gear. This buoyant, strong, and biodegradable material can be “grown” into fish floats, fly-fishing bobbers, and more!